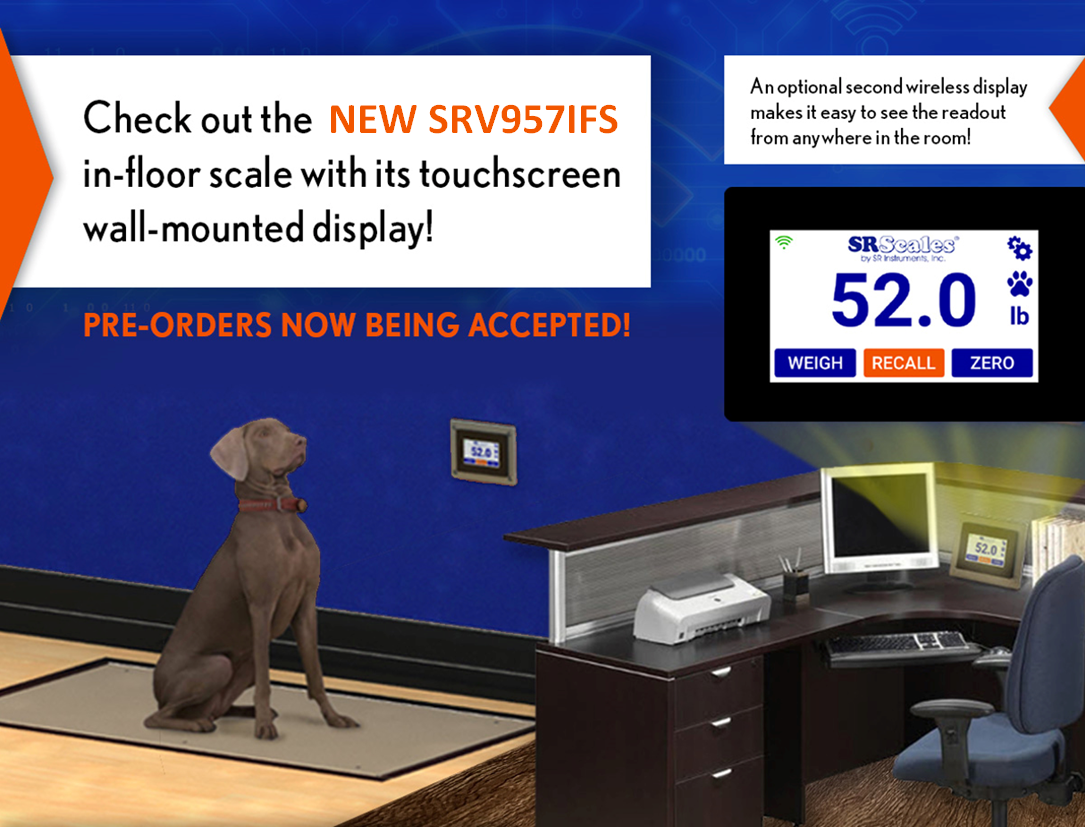

New Touchscreen Display Coming Soon to a Veterinary Scale Near You!

SR’s top-of-the-line in-floor veterinary scale, the SRV947IFS, has been a proven workhorse scale solution at leading veterinary facilities for years. Before construction even begins on